Ecology & Living Space

New Challenges Focused on Changing Times

ELS Division responds to a wider variety of “environments”

“ELS” in the ELS Division stands for Ecology and Living Space.

The division was renamed in 2020 with the aim of expanding its business domain to the field of living environment as well as natural energy, centered on the solar cell business.

In order to contribute to the environment with our unique technology, we have taken on the challenge of manufacturing and developing solar cells by applying precision bonding technology cultivated through the manufacturing and process development of optical filters for flat-screen TVs.

For the next generation, which continues to change, we aim to further apply technology and develop our business by redefining the definition of the environment to “living space = a place where people live.”

Expand the Future~ Renewable Energy Field ~

The field of renewable energy, centered on the solar cell business, is the mainstay of the ELS Division.

Based on the expertise we have accumulated through the manufacturing of solar cell modules, we continue to work on lightweight and flexible modules, BIPV, and next-generation solar cells.

New Applications for Technology~ Living space ~

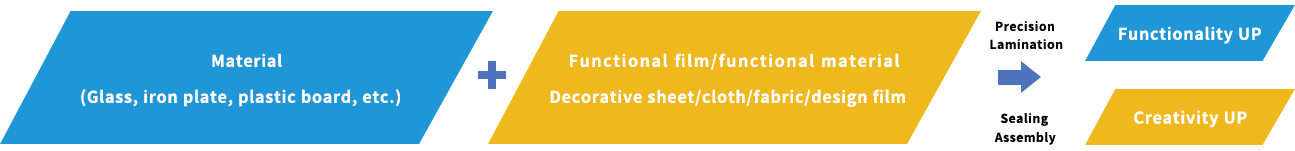

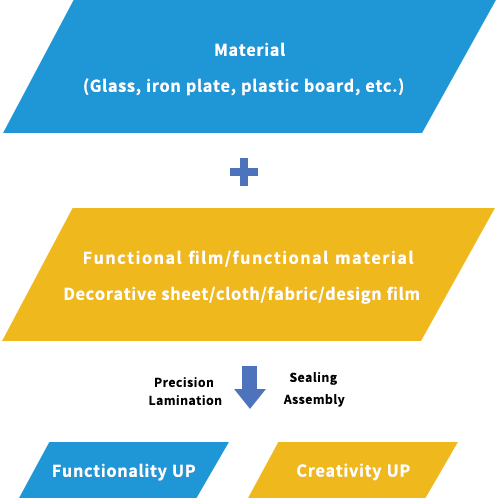

The ELS Division will create new value for materials by applying our proprietary precision laminating technology and encapsulation technology cultivated through the manufacture of solar cells to the environment and living spaces.

By combining materials, new functions and designs can be added to living spaces.

Fujipream’s technology is in places you can’t see.

Our products are at work in places like these.

Fujipream in

your daily life.

-

- Rooftops and gardens

-

-

- Living-dining

kitchen -

- Living-dining

-

- Roads/Cars

Aircraft -

- Roads/Cars

-

- Communication

Security/actuator -

- Communication

Factory Facilities

PV Plant

| Factory floor area | Approximately 2,560㎡ (2F), approximately 1,920㎡ (1F) |

|---|---|

| Warehouse area | Approximately 1,920㎡ |

| Main equipment | laminated glass laminator solar cell solar simulator Solar cell EL inspection device Other various devices |

Koto Plant

| Clean room area | Approximately 3,700㎡ |

|---|---|

| Cleanliness | class 1000 |

| Main equipment | precision laminating machine cutting machine autoclave Dispenser screen printing machine washing machine slit coater Other various devices |

Koto Plant No.3

| Clean room area | Approximately4,300㎡ |

|---|---|

| Cleanliness | class 1000 |